Build a digitally connected ecosystem with Schneider Electric's Harmony Hub

Ask for a demonstration and experience the benefits and possibilities!

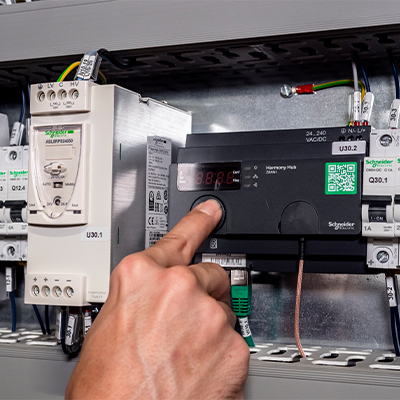

Harmony Hub is a wireless system based on the generic ZigBee communication protocol for your existing industrial plants and processes. Collect concrete signals from a control panel and generate data via wireless components such as limit switches, push buttons and sensors.

Data collection via the Harmony Hub

With the Harmony Hub, you can link up to 60 different wireless components. Easily connect wireless push buttons, sensors or pull cord switches. Through the Harmony Hub, you build a connected ecosystem with wireless products that work together, generate data and offer new insights. This makes it possible to quickly monitor machines or locate pressed emergency stop buttons, for example. With the Harmony Hub, you build a digitally connected ecosystem in a way never before possible.

Wireless control with the Harmony Hub

The Harmony Hub goes beyond data generation, making industrial processes more efficient and flexible. Wireless connectivity allows operators to operate machines remotely faster and more efficiently. Dangerous situations are also avoided by eliminating cabling. This enables operators to do their work at a safer distance. In short, Harmony Hub ensures speed, full mobility and flexibility of your industrial applications.

Getting started with Harmony Hub yourself?

Would you like to experience the benefits and capabilities of Harmony Hub for yourself? Then request a demonstration by filling in the form below. During the demonstration, we will show you how to simplify the control of your equipment with wireless connectivity. You will also get information on how the solutions contribute to cost savings, time savings and improved safety in the workplace. Fill in the form and we will contact you as soon as possible!

Yes, I would like a demonstration of the Harmony Hub

Stay up to date with the latest news:

-

nVent Hoffman - Simplify sanitary processes, prevent contaminationRead moreProtect critical electrical equipment with easy-to-clean, washable enclosures to maintain hygienic conditions and protect products Food and beverage manufacturers must implement advanced sanitation solutions to ensure consumer health and safety worldwide and protect their business from costly downtime and recalls. Electrical enclosures are among the crucial equipment in any food processing plant and play a vital role in maintaining these high hygiene standards.

-

Stahl Electromach - Explosion-proof linear luminairesRead moreR. STAHL's explosion-proof linear luminaires and LED lighting solutions feature advanced, innovative LED technology. They come standard with electrical connections on both ends, five-core through-wiring, and a new sealing system ensuring a certified IP66/IP67 protection rating. The electronic ballast, mounted on the reflector plate of the LED luminaires, enhances the maintenance-friendliness of the Ex linear luminaires. Whichever version you choose to install in your environment, with R. STAHL, you're in safe hands.

-

Schneider Electric - Software-defined automationRead moreSoftware-defined Automation (SDA) is a new approach to industrial automation that uses software to control, manage and optimize automation processes instead of the traditional “hardware-first” approach to automation.

-

3M - Tapes for moisture sealing tasksRead moreReliable protection for moisture sealing tasks in, for example, irrigation, refrigeration, cleaning areas in factories, outdoor lighting, marine environments and other infrastructure exposed to the elements.

Check out our other success stories:

Why not take a look at these trainings we offer:

-

TIAP-NETWORKRead moreavailable in Dutch

-

PROFIBUS-Troubleshooting & MaintenanceRead moreavailable in Dutch

-

PROFINET - Troubleshooting & MaintenanceRead moreavailable in Dutch